Ishubhu Elingenamthungo Elicwebezelayo (BA) Elicwebezelayo

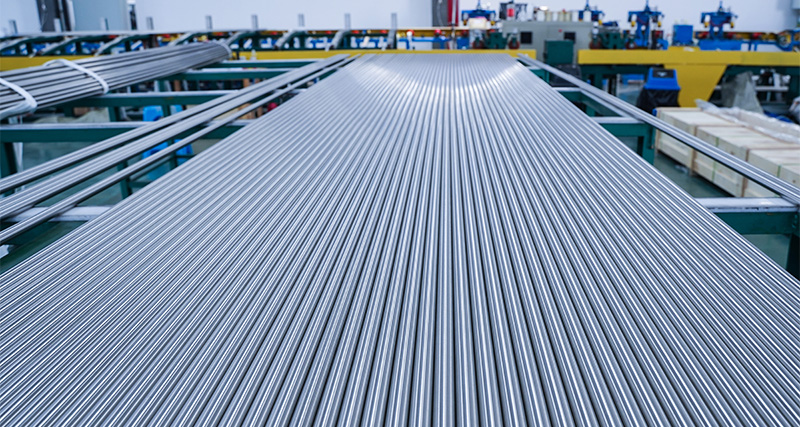

Incazelo Yomkhiqizo

Uku-annealing okukhanyayo inqubo yoku-annealing eyenziwa endaweni evalekile noma emoyeni olawulwayo oqukethe amagesi angasebenzi (njenge-hydrogen). Lo moya olawulwayo unciphisa uku-oxidation kobuso kube kuncane okuholela endaweni ekhanyayo kanye nengqimba ye-oxide encane kakhulu. Uku-pickling akudingeki ngemuva koku-annealing okukhanyayo ngoba uku-oxidation kuncane. Njengoba kungekho uku-pickling, ubuso bubushelelezi kakhulu okuholela ekumelaneni okungcono nokugqwala kwemigodi.

Ukwelashwa okukhanyayo kugcina ubushelelezi bendawo egoqiwe, futhi indawo ekhanyayo ingatholakala ngaphandle kokucutshungulwa ngemuva. Ngemva kokunamathisela okukhanyayo, indawo yepayipi lensimbi igcina ukukhanya kwensimbi kwasekuqaleni, futhi indawo ekhanyayo eduze kwendawo yesibuko itholakale. Ngaphansi kwezidingo ezijwayelekile, indawo ingasetshenziswa ngqo ngaphandle kokucutshungulwa.

Ukuze i-annealing ekhanyayo isebenze kahle, Sihlanza izindawo zamapayipi futhi azinazo izinto zangaphandle ngaphambi kokufaka i-annealing. Futhi sigcina umoya we-annealing wesithando ungenawo umoya-mpilo (uma kudingeka umphumela okhanyayo). Lokhu kufezwa ngokususa cishe yonke igesi (ukudala i-vacuum) noma ngokususa umoya-mpilo ne-nitrogen nge-hydrogen noma i-argon eyomile.

I-vacuum bright annealing ikhiqiza ipayipi elihlanzekile kakhulu. Leli payipi lihlangabezana nezidingo zemigqa yokuphakelwa kwegesi ehlanzekile kakhulu njengokushelela kwangaphakathi, ukuhlanzeka, ukumelana nokugqwala okuthuthukisiwe kanye nokunciphisa ukukhishwa kwegesi nezinhlayiya kusuka ensimbini.

Le mikhiqizo isetshenziswa ezintweni zokunemba, imishini yezokwelapha, ipayipi lokuhlanzeka okuphezulu embonini ye-semiconductor, ipayipi lezimoto, ipayipi legesi lelebhu, uchungechunge lwezindiza kanye nemboni ye-hydrogen (umfutho ophansi, umfutho ophakathi, umfutho ophakeme) ipayipi lensimbi engagqwali le-Ultra high pressure (UHP) kanye neminye imikhakha.

Siphinde sibe nempahla engaphezu kwamamitha ayi-100,000 yepayipi, engahlangabezana namakhasimende ngezikhathi zokulethwa eziphuthumayo.

Ibanga Lezinto Ezibalulekile

| I-UNS | I-ASTM | EN |

| S30400/S30403 | 304/304L | 1.4301/1.4307 |

| S31603 | 316L | 1.4404 |

| S31635 | I-316Ti | 1.4571 |

| S32100 | 321 | 1.4541 |

| S34700 | 347 | 1.4550 |

| S31008 | 310S | 1.4845 |

| N08904 | 904L | 1.4539 |

| S32750 | 1.441 | |

| S31803 | 1.4462 | |

| S32205 | 1.4462 |

Imininingwane

I-ASTM A213 /ASTM A269/ASTM A789/EN10216-5 TC1 noma ngokwezidingo.

Ubulukhuni Nokuqina

| Izinga Lokukhiqiza | Ubulukhuni Bangaphakathi | Ubuso be-OD | Ubukhulu bokuqina | ||

| Uhlobo 1 | Uhlobo 2 | Uhlobo 3 | Uhlobo | I-HRB | |

| I-ASTM A269 | URa ≤ 0.35μm | URa ≤ 0.6μm | Akukho sicelo | IsiPolish Semishini | 90 |

Inqubo

Ukugoqa okubandayo / Ukudweba okubandayo / Ukunamathisela.

Ukupakisha

Ithubhu ngalinye liboshwe kuzo zombili izinhlangothi, lipakishwe ezikhwameni ezihlanzekile ezinesendlalelo esisodwa bese lifakwa ebhokisini lokhuni.

Isicelo

Amakhemikhali kanye ne-petrochemical/ Amandla kanye namandla/ Ukukhiqizwa kwe-heat exchanger/ Izinhlelo ze-hydraulic kanye ne-mechanical/ Ukuhanjiswa kwegesi okuhlanzekile

Isitifiketi Sokuhlonipha

Izinga le-ISO9001/2015

Izinga le-ISO 45001/2018

Isitifiketi se-PED

Isitifiketi sokuhlola ukuhambisana kwe-TUV Hydrogen

Imibuzo Evame Ukubuzwa

- Ukugcwalisa Okuphelele.

- Ukufakwa kwe-Isothermal.

- Ukufakwa kwe-Annealing okungaphelele.

- Ukufakwa kwe-Spherification.

- Ukusabalala, noma i-Uniform, i-Annealing.

- Ukuqeda Ukucindezeleka.

- Ukuvuselelwa kwe-Annealing.

I-Annealing inqubo yokwelapha ukushisa eshintsha izakhiwo zomzimba futhi ngezinye izikhathi zamakhemikhali zento ukuze kwandiswe ukuguquguquka kwayo futhi kuncishiswe ubulukhuni ukuze isebenze kalula. Inqubo ye-annealing idinga ukuthi into ibe ngaphezu kwezinga lokushisa layo lokuphinda isetshenziswe isikhathi esithile ngaphambi kokuba iphole.

I-Annealing inqubo yokwelapha ukushisa esetshenziselwa ukushintsha izakhiwo zensimbi nezinye izinto, ngokuvamile ukuzenza zithambile, ziqine kakhulu, futhi zingaqhekeki kakhulu. Kuhilela ukushisa izinto zibe yizinga lokushisa elithile bese ziphola kancane ngendlela elawulwayo, ukuze kulawulwe isakhiwo sekristalu.

| Cha. | Usayizi(mm) | Usayizi we-EP Tube (316L) Kuphawulwe ngu-● | |

| I-OD | Thk | ||

| I-BA Tube Ubulukhuni bomphezulu wangaphakathi Ra0.35 | |||

| 1/4″ | 6.35 | 0.89 | ● |

| 6.35 | 1.00 | ● | |

| 3/8″ | 9.53 | 0.89 | ● |

| 9.53 | 1.00 | ||

| 1/2” | 12.70 | 0.89 | |

| 12.70 | 1.00 | ||

| 12.70 | 1.24 | ● | |

| 3/4” | 19.05 | 1.65 | ● |

| 1 | 25.40 | 1.65 | ● |

| I-BA Tube Ubulukhuni bomphezulu wangaphakathi Ra0.6 | |||

| 1/8″ | 3.175 | 0.71 | |

| 1/4″ | 6.35 | 0.89 | |

| 3/8″ | 9.53 | 0.89 | |

| 9.53 | 1.00 | ||

| 9.53 | 1.24 | ||

| 9.53 | 1.65 | ||

| 9.53 | 2.11 | ||

| 9.53 | 3.18 | ||

| 1/2″ | 12.70 | 0.89 | |

| 12.70 | 1.00 | ||

| 12.70 | 1.24 | ||

| 12.70 | 1.65 | ||

| 12.70 | 2.11 | ||

| 5/8″ | 15.88 | 1.24 | |

| 15.88 | 1.65 | ||

| 3/4″ | 19.05 | 1.24 | |

| 19.05 | 1.65 | ||

| 19.05 | 2.11 | ||

| 1″ | 25.40 | 1.24 | |

| 25.40 | 1.65 | ||

| 25.40 | 2.11 | ||

| 1-1/4″ | 31.75 | 1.65 | ● |

| 1-1/2″ | 38.10 | 1.65 | ● |

| 2″ | 50.80 | 1.65 | ● |

| 10A | 17.30 | 1.20 | ● |

| 15A | 21.70 | 1.65 | ● |

| 20A | 27.20 | 1.65 | ● |

| 25A | 34.00 | 1.65 | ● |

| 32A | 42.70 | 1.65 | ● |

| 40A | 48.60 | 1.65 | ● |

| 50A | 60.50 | 1.65 | |

| 8.00 | 1.00 | ||

| 8.00 | 1.50 | ||

| 10.00 | 1.00 | ||

| 10.00 | 1.50 | ||

| 10.00 | 2.00 | ||

| 12.00 | 1.00 | ||

| 12.00 | 1.50 | ||

| 12.00 | 2.00 | ||

| 14.00 | 1.00 | ||

| 14.00 | 1.50 | ||

| 14.00 | 2.00 | ||

| 15.00 | 1.00 | ||

| 15.00 | 1.50 | ||

| 15.00 | 2.00 | ||

| 16.00 | 1.00 | ||

| 16.00 | 1.50 | ||

| 16.00 | 2.00 | ||

| 18.00 | 1.00 | ||

| 18.00 | 1.50 | ||

| 18.00 | 2.00 | ||

| 19.00 | 1.50 | ||

| 19.00 | 2.00 | ||

| 20.00 | 1.50 | ||

| 20.00 | 2.00 | ||

| 22.00 | 1.50 | ||

| 22.00 | 2.00 | ||

| 25.00 | 2.00 | ||

| 28.00 | 1.50 | ||

| I-BA Tube, Akukho sicelo mayelana nokuqina kobuso bangaphakathi | |||

| 1/4″ | 6.35 | 0.89 | |

| 6.35 | 1.24 | ||

| 6.35 | 1.65 | ||

| 3/8″ | 9.53 | 0.89 | |

| 9.53 | 1.24 | ||

| 9.53 | 1.65 | ||

| 9.53 | 2.11 | ||

| 1/2″ | 12.70 | 0.89 | |

| 12.70 | 1.24 | ||

| 12.70 | 1.65 | ||

| 12.70 | 2.11 | ||

| 6.00 | 1.00 | ||

| 8.00 | 1.00 | ||

| 10.00 | 1.00 | ||

| 12.00 | 1.00 | ||

| 12.00 | 1.50 | ||